Chemicals are part of our daily life. Every living & non-living matter is made of chemicals & almost all man-made products involve the use of chemicals. Many chemicals can significantly contribute to the improvement of life, health & well-being. Even there are some “feel-good” chemicals released from our brain like Endorphin, Dopamine. However some other chemicals are really hazardous & can adversely impact our health, environment & even society if not properly managed.

According to a WHO Report, “In 2004 at least 4.9 million deaths (8.3% of all deaths) were due to environmental exposure to selected chemicals.” One of the main reasons and sources of discharged chemicals in the atmosphere is the textile industry.

It is a known fact that humans always try to look appealing & glamorous. To do so they have ended up harming the environment through textile industry and the process of “from fibre to fashion”. The chance of harm is more in India, as most of its apparel industries are in unorganized sectors and they are far behind the international standards in productivity and quality.

As a part of manufacturing sector, textile industry has been one of the important sectors to contribute towards the country’s economy. This sector occupies a unique position in employment generation – second largest after agriculture. The textile industry includes various stages from ginning to knitting. Before industrial revolution, all fabrics were produced by hand from start to finish. The human labor involved made the fabric very expensive. Day by day, the situation changed and fashion became a chemical thirsty industry from cultivation to final process. Till date cultivated agro-cotton has not been able to overcome its chemical addiction. Sadly, some of the most harmful insecticides like Endosulfan used as agro-chemicals are well known for developing disability in children. Textile production has its harmful impacts on environmental aspects such as air, water, land and human; and social aspects such as child labor and poor unhygienic working conditions. It is really shocking that textile industry is one of the greatest consumers of water per kg of produced material. Some of the chemicals, like dyes and finishing agents, reside in the final apparel. As clothes are worn in close contact to the skin, humans are exposed to these chemicals. The story doesn’t end here. Such chemicals remain in the air, water and soil causing environmental pollution. This draws strong attention to detect & control chemicals & pollutants discarded into human skin and environment.

Almost each & every step like washing and scouring of fibers and yarn; bleaching and dyeing of yarn and cloth, printing and finishing of cloth and garment needs chemicals to be applied. Naturally, a question arises here, why does the textile industry use so many chemicals? Actually, most fabrics are finished in a process called “wet processing”, where the whole process is accomplished by applying liquids. Wet processing has become very popular for its lesser cost. On the other hand, “dry processing” is a mechanical/physical treatment generally avoided for its higher cost.

To summarize, there are various stages involved in textile manufacturing like pretreatment (desizing, scouring, bleaching, & mercerizing), dyeing, printing, finishing, washing, and drying. A little representation of some steps will reveal the chemical treatment and discharge:

Pretreatment: Performed on the fibre to remove undesired material and improve the quality for dyeing, printing and finishing treatments. This process uses compounds like anionic or non-ionic surfactants (e.g. alcohol ethoxylate, and alkyl phenol ethoxylate), hypochlorite or chlorite and hydrogen peroxide.

Dyeing: Process to color textile material – the fiber, yarn, fabric or final product with azo dyes, anthraquinone dyes, acidic dyes, reactive dyes or metal complex dyes. The issue of carcinogenicity related to various dyes like azo dyes is a hot topic of research nowadays. Also, such untreated dye effluents are released into freshwater sources posing threat to the planet.

Printing: Method to add pigments on the textile to give specific patterns; e.g. graphics on the apparel. Dyes, pigments & chemical solvents are the most common chemicals used.

Finishing: All treatments, mechanical or chemical performed on fibre, yarn or fabric in order to improve look and texture. Possible pollutants in this phase are formaldehyde, flame-retardants, antistatics, softening and biocides.

Effluents from textile dyeing are difficult to treat as they have high content of pollutants like polycyclic aromatic hydrocarbons, heavy metal ions, surfactants, dyes, solvents, detergents and recalcitrant compounds. The chemicals in the effluents include unutilized dyes, acid, soap, detergent, enzymes, dye fixing agent, chlorinated stain removers, chromium compound, heavy metals and some auxiliary chemicals. They make the effluents highly toxic. These hazardous substances remaining in the fabric can be transferred to the outermost layer of the skin leading to various skin problems. Textile clothes, bed linen, towels and articles of daily use can pose this hazard.

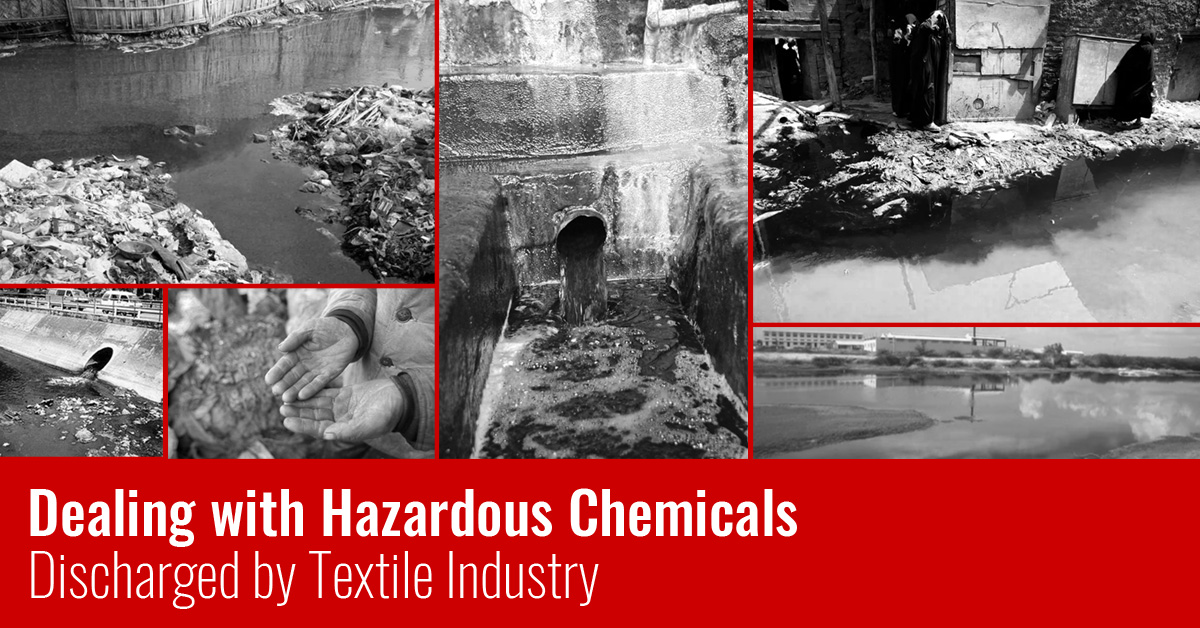

These toxic effluents cause destruction of earth’s natural resources by polluting land, water and air. They also cause heavy disease burden to human & shorten human life expectancy. Not only this, chemicals present in the effluents make the water harmful for biotic and aquatic life. The emissions of carbon tetra-chloride and carbon dioxide destroy the stratospheric ozone layer and stimulate global warming.

It is therefore important to note that without proper monitoring and surveillance or strict regulations, textile effluents and chemicals present in them can be a serious and significant cause of environmental pollution. India is among the first countries in the world that has provided in its constitution protection and improvement of environment. However, there are no specific environmental laws for textile sector alone. The Indian environmental legislation is very stringent, however poorly enforced. We should understand that only making laws doesn’t help. Environment is a social responsibility. Policies can help – but the desirable compliances should come voluntarily from the industries, not from the policies.